There are several kinds of metal-melting furnaces, each with its own distinct qualities. These are some of the most prevalent kinds of metal melting furnaces, although they are slightly different from a gold melting furnace, but almost feature the same principles.

Arc Furnace

The arc furnace is one of the most prevalent forms of metal melting furnaces. This kind of furnace employs an electric arc to convert scrap metal into a liquid state by melting it. These furnaces are very hazardous and should only be used by experts.

Batch Melting Furnace

A batch melting furnace is a big piece of equipment that simultaneously melts down enormous amounts of scrap metal. This sort of furnace is ideal for industrial environments in which numerous individuals must liquefy scrap metal.

Batch Smelting Furnace

A batch smelting furnace is similar to a batch melting furnace, except that it employs electricity as its heat source instead of an electric arc. It may also be employed in industrial environments where numerous individuals must simultaneously melt scrap metal.

Induction Heaters

Induction furnaces are used to melt aluminium, copper, and magnesium alloys that may be heated to temperatures between 900°C (1,650°F) and 1,300°C (2,370°F). At the bottom of induction furnaces is an electric coil that creates heat by electromagnetic induction. This coil is enclosed by a firebrick or graphite block refractory liner. The ingots of metal are put in a crucible inside this liner, which functions as a conductor for the electromagnetic waves generated by the coil. Through this conductor, electromagnetic waves heat metal ingots to temperatures exceeding their melting points.

Hearth Furnaces

The earliest form of metal-melting furnaces are hearth furnaces. Since antiquity, they have been used to melt iron and steel. Hearth furnaces consist of a firebox where the fire burns, a hearth that contains the charge of metal to be melted, and a refractory lining that prevents heat escape through the walls. Clay bricks or terracotta tiles are often used to construct the fireplace, since they are affordable and readily available. However, these sorts of fireplaces do not permit air circulation, making it impossible to regulate the temperature of the molten metal in the furnace.

Electric Furnaces

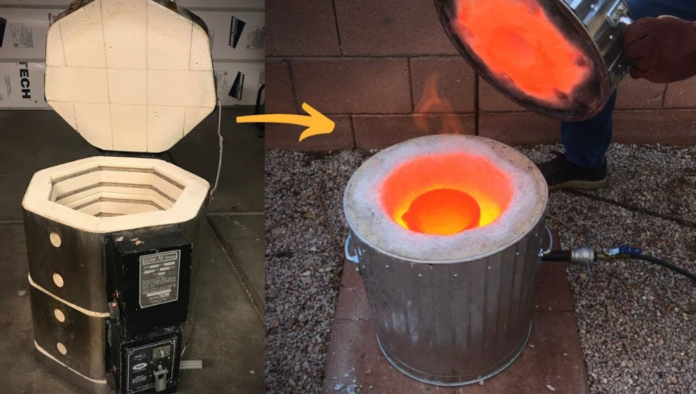

In the metalworking sector, electric furnaces are the most prevalent form of furnace. They are sometimes referred to as induction furnaces since they use an electromagnetic field to heat metal. The precise controllability of this kind of furnace enables the melting and processing of tiny quantities of metal. Electric furnaces use far less energy than other kinds of furnaces, but are more costly to purchase and install.

Cupola Furnaces

Cupola furnaces are used to melt tiny quantities of metal and may be fueled by either electricity or gas. Cupola furnaces get their name from its similarity to the cupola atop a structure. They were initially employed in foundries because they could simultaneously melt vast quantities of metal, rather than waiting for each piece to be separately melted in a crucible.

Cupola furnaces offer several benefits over other kinds of furnaces since they may be run wherever electricity or gas is available and do not need additional ventilation systems for safe operation. Cupolas are available in capacities ranging from 25 pounds to 10 tons, depending on the magnitude of the work.

Conclusion

Depending on a variety of criteria, the kind of melting furnace you pick for your metal melting facility will vary. The kind of metal melted in your production is an important consideration; if the metal melted in your manufacturing is mostly ferrous, an electric arc furnace would be an appropriate option.

You should prioritize selecting a furnace that suits your particular demands and specifications. There is no one furnace capable of melting all metals. And although a basic furnace may not have the same capabilities as a more sophisticated one, it may still serve its purpose if that is all you need.