Many manufacturing processes are too costly or take too long to produce your customers’ prototypes and final parts. If you want to create your prototypes and parts but don’t know the best way to do it, this is the right place to learn.

There has been a rise in 3D prototyping within engineering, design, and art production. Although 3D models are gaining in popularity, there are still many questions about their functionality and the process of creating them. CNC machining solves both problems by being highly cost-effective and taking just a few days to complete, making it the perfect way to get your products out on time and within budget.

With CNC machining, you can craft various parts quickly and affordably. But don’t take our word for it — see what others are saying about our process here!

Let us find out more reasons why CNC machining is the best way to manufacture complex parts.

Easily Operatable With Greater Safety Systems

The CNC machining system is easily operatable with excellent safety. CNC machining is controlled by a computer and is often used for mass production. It can significantly reduce the human labor for machining, which results in higher efficiency, better accuracy, and reduced cost.

The simpler the system and the less complicated its structure, the easier it is to use. CNC machining systems are designed with ease of use in mind. They have a user-friendly and ergonomic design to ensure that they can be operated with more excellent safety.

CNC machining is among the most flexible and efficient technologies used in modern industries. As a result of its versatility, CNC machining has gained popularity amongst many companies, thanks to the fact that it can be tailored to meet specific requirements.

Advance Fabrication Systems

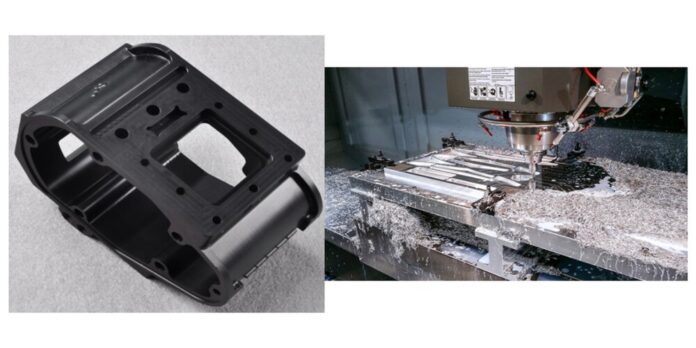

The CNC machining system has advanced fabrication systems, a solution for custom parts required by the automotive, aerospace, and defense industries. The equipment used in the process is high precision, allowing for a variety of product types and shapes to be made easily.

Fabrication is the process of creating a part from raw materials. In manufacturing, fabrication is usually followed by the assembly, which puts together sub-assemblies, smaller parts, and components to make final products. Advance Fabrication Systems provides CNC machining services for companies who want affordable tools for their machine shop.

It can complete the job more quickly and precisely, which helps people save money. The advanced software in this machine is easy to handle and work with, so everyone can use it easily.

Less Waste Of Material

The CNC machining system can decrease material waste by using high-accuracy machining tools that can reduce the amount of scrap. The production line also goes directly from the machine to a bin for storage, which means parts are not transported to another location and are damaged more during transport.

CNC machining is a cutting process that utilizes computer numerical control (CNC) to remove excess material from a workpiece. The basic concept of CNC machining is that it uses the same design and layout to produce several parts at once.

CNC machining is most common in the manufacturing sector, where it can reduce material waste by as much as 60%.